It is a fact that the commercial promotion activity of DEUTZ Italy, through its Marine & Power business unit (hereinafter DMP b.u.) seems to have no limits in terms of territory. This becomes possible when your customer portfolio includes multinational companies, with branches and operations on all continents. Such is Nuovo Pignone, a Baker Hughes company, with which DEUTZ Italy has been pleased to collaborate for over two decades as a supplier of stationary engines and power plants for Oil & Gas applications.

DEUTZ Italy’s cooperation with Nuovo Pignone

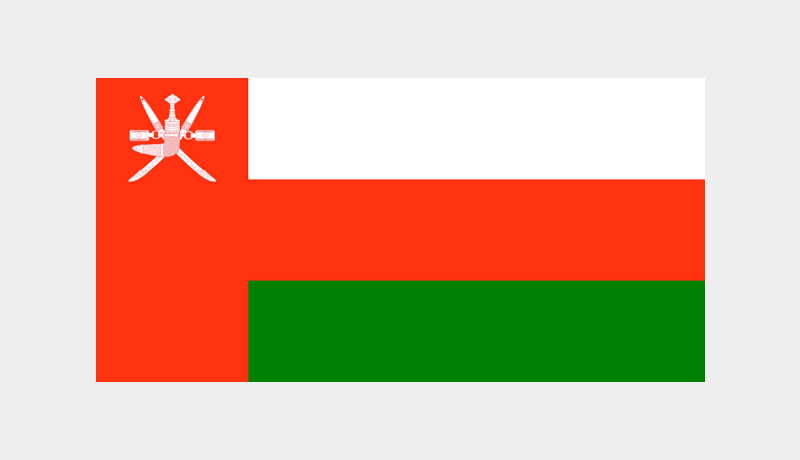

This also happens this year thanks to the excellent relationship with Nuovo Pignone, one of the historic Italian companies in the field of mechanics applied to large oil & gas plants. In the last years of its activity it has specialized in the installation and subsequent O&M of equipment for handling hydrocarbons and gases. The Nuovo Pignone brand is known throughout the world for its reliability in the management of the most important and demanding orders. One of the industrial sites where Nuovo Pignone operates is located in Oman and it is there that two MWM / DEUTZ motors, now obsolete, will be replaced with as many motors of equivalent power, but equipped with more modern control systems and the greater safety requirements required by the end customer.

Nuovo Pignone inside the Baker Hughes Group

Nuovo Pignone, formerly part of General Electric, has recently joined the group of a service company applied to large industrial plants operating globally. We are talking about Baker Hughes, a company based in Houston, United States, even though its main base of operations is in another U.S. state, Delaware.

The DEUTZ engines at the service of large crude oil extraction plants

This company offers engineering services, O&M and EPC to large global companies. Their activities cover a series of advanced services that support large industrial plants that are scattered all over the world. The main branch of activity of the Baker Hughes Company focuses on crude oil services. In fact, the company is one of the most appreciated companies in the world when it comes to supply and services for drilling rigs meant for the extraction of crude oil and natural gas. Their activities spread from the deposit’s design to the finishing, the evaluation, and its technical support.

LNG (liquified natural gas) extraction plant in Qalhat, Oman

The end customer for the engines described in this article is Oman LNG, a company that was founded in 1994 following the royal decree issued by Qaboos, the sultan of Oman. This company was created for the purpose of building and managing LNG extraction plant that is situated in Qalhat. This location is in Oman, on the coast near Sur and it is situated in the area that is governed by the South Shargiyah’s administration. The site boasts of an annual handling of 10.4 million GNL. The plant in which Baker Hughes operates was commissioned in September 2000.

Delivery of Engines to Oman LNG

The two-engine-supply involves the replacement of the existing two engines that were installed at the site in the early 90s. In this case, the choice fell on two diesel 4 stroke high speed diesel engines built by Cummins and re-engineered by DEUTZ Italy in order to make them compliant to the new and stringent safety requirements in an explosive setting on the OLNG site. Each of the engines is rated 522 kW (700 Bhp) at 2100 RPM. The new engines come with technological innovations that make them compliant with the ATEX 2014/34/EU directive. The start-up and commissioning of the two engines by DMP b.u. is expected to happen within Q2 2022.